|

The

End of the Age of Oil 2005 - 2025 The

End of the Age of Oil 2005 - 2025

Increasing

Demand, Falling Supply

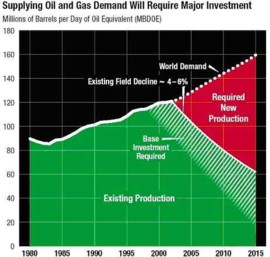

In

January 2005, ExxonMobil presented this graph to institutional

investors in New York.

It

shows oil production from existing fields now declining

by 4-6% p.a. while demand increases by 1.7% p.a.

By

2020, required new oil production alone

will have to equal total current global production to

keep up with demand.

One

third of World Oil Production now comes from declining

fields.

Oil

production has plateaued or is in decline in 33 of the

48 major oil producing nations including 6 of the 11

OPEC members.

By

2030, production from today's oil fields will have fallen

from 85Mb/d to 30Mb/d.

"The

World needs 10 new Saudi Arabias"

- Sadad Al Husseini, Head of Exploration, Saudi Aramco.

Analysis

by ODAC

of planned new oil field developments shows that after

2007, a seemingly unbridgeable gap opens up between

oil demand and supply. There is a rapid drop off in

new mega-project developments after 2006: by 2008 demand

will become constrained by a supply which has fallen

into decline.

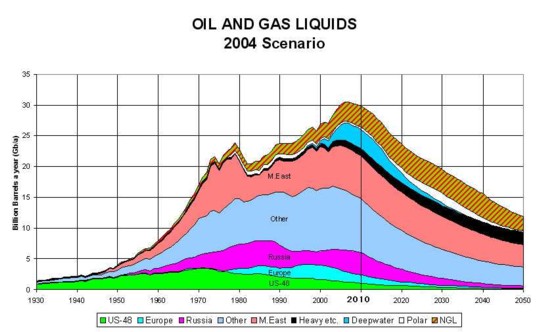

The

latest analysis from the ASPO

indicates that oil production may already have reached

the Hubbert Peak or be about to do so. The graph below

was presented at the first ASPO workshop in Uppsala

in 2002.

Oil

Consumption Reduction Programme

90%

of our transportation is dependent on oil. 66% of US

oil consumption is used for transportation alone.

Reducing

the overwhelming reliance and dependence of our Road

Transportation systems on fossil fuel must be the immediate

priority.

A

Global Oil Consumption Reduction Programme must be implemented

forthwith to conserve oil supplies and implement alternative

sources of propulsion.

This

requirement to reduce oil dependence presents an enormous

Market Opportunity for the alternative energy and alternative

propulsion technology sectors. Those companies that

position themselves now to take advantage of the forthcoming

transition away from fossil fuel will achieve spectacular

growth.

The

Solution - The Plug In Hybrid and Battery Electric Vehicles

There

is one main technology available today that can reduce

oil consumption sufficiently in the timescale required

- the Plug-In Hybrid and the pure Battery Electric Vehicle.

The

Plug In Hybrid Electric Vehicle can offer 2 - 8 times

the fuel economy of the Internal Combustion Engine

Vehicle.

The

Battery Electric Vehicle (BEV) is some 10 times more

energy efficient than the internal combustion engine.

It is by far the most efficient form of road vehicle

possible.

The

Solution to the Peak Oil situation is simple. To mandate

that all new Light Vehicles sold must have a minimum

fuel economy of 100 miles per US gallon.

This

efficiency is now being demonstrated by a growing US

fleet of Toyota Priuses, retrofitted with larger plug

in batteries.

The

Daihatsu UFE II and III Hybrid prototypes have demonstrated

over 160mpg.

The

pure Battery EV demonstrates the greatest oil saving

of all. Apart from that, the cost of running a BEV in

Europe or the USA would be less than 10% of the cost

of an Internal Combustion Engine Vehicle (ICEV). Less

than 150 euros or dollars per year.

With

the latest battery technology, the BEV need no longer

be subject to limited range but can be designed with

a range comparable to petrol and diesel vehicles.

With

current technology, the Plug In Hybrid EV and the pure

Battery EV can complement each other for different markets:

the hybrid for assured longer range, the BEV for local

and urban use.

If

we implement a program to convert as much road transportation

to hybrid or pure electric power as possible, along

with expansion in biofuels where possible and adoption

of enhanced fuel efficiency technologies for the internal

combustion engine, we will have a viable pathway to

overcoming our dangerous dependence on fossil fuel and

to reducing oil consumption to manageable levels.

Conversion

of Road Haulage and Public Transport to Electric Propulsion

would have proportionately greater petroleum saving

benefits and should be prioritised.

Public

Transport and Utility fleets could be converted to Electric

Propulsion immediately with no inconvenience or change

required in operating patterns.

Central

Electricity Generation

The

total electricity required to power the whole UK road

vehicle fleet by electric propulsion would be at most

15% of the electricity currently generated in the UK.

Compared

with the 29 billion litres of fuel sold in the UK in

2001, it is clear how much more efficient and less polluting

Electric Propulsion would be.

Studies

indicate that at least 20% of the German car fleet could

be converted to electric power for no penalty; they

could be recharged overnight from off peak capacity

that is currently unused. In the Netherlands, the percentage

of the car fleet that could be powered by unused off-peak

capacity was put at 20-60%. We have a ready made buffer

already existing that can be used to reduce petroleum

consumption.

Load

levelling to reduce the differences between peak and

off-peak demand is of major importance for efficient

electricity generation. An EV fleet that recharges overnight

from off peak electricity would be of major benefit

to central electricity generating stations.

The

official electricity transmission losses alone in the

UK would power about 10% of the whole UK road vehicle

fleet. Technology exists to reduce these losses still

further.

In

the USA, the American Council for an Energy Efficient

Economy estimate that 24% of current US electricity

consumption could be easily saved. If this saving was

applied exclusively to power the US Light Vehicle Fleet,

US car drivers could drive 33% further than they do

today, replace all their petrol with electricity and

need generate no more electricity than they do today.

9.1Mb/d of oil would be saved.

Therefore

any requirement to build new electricity generating

capacity to power an EV fleet can be minimised: renewable

energy and CHP would be the most efficient ways to supply

this.

EV

Example - The GM EV1

The

GM EV1 is the only dedicated Electric Car design to

have entered series production in recent times. With

modern NaNiCl batteries, its range between recharging

could be more than doubled to 300 miles. The

GM EV1 is the only dedicated Electric Car design to

have entered series production in recent times. With

modern NaNiCl batteries, its range between recharging

could be more than doubled to 300 miles.

Like

all the EVs introduced in minimal numbers in the late

1990s to meet the CARB rules, the 2 seater EV1 was handicapped

by lack of marketing and a prohibitive price - $500

per month for the improved 1999 version.

In

2005, General Motors crushed most of the EV1s that were

manufactured and removed it from the Smithsonian Museum.

The EV1 was the most aerodynamically efficient car ever

produced.

2007:

Peak Oil - The

EV Imperative

For

more information see 2007:

Peak Oil - The EV Imperative

|