| Since

all interactions of a solid body with a fluid, be it bird,

fish, aeroplane or ship, involve the flow of fluid over

a solid boundary, it can be said that Fluid

Dynamics IS the Science of the Coanda Effect.

The

Coanda Effect has come to mean attachment of a flow

to a surface beyond where we "expect" it to remain attached

- but this is a scientifically meaningless view.

The

classic example is that of fluid pouring out of a bottle

or teapot. If the fluid does not pour straight out but

flows around the lip, reversing direction before finally

succumbing to gravity and detaching, this effect of

"sticking to the surface" has come to be called the

"Coanda Effect".

A

more interesting example that anyone can perform for

themselves is to allow a fine continuous stream of water

to issue from the kitchen tap. Bring the rounded

pad of your first finger towards the stream until it

just touches. With the finger barely touching

the flow, the stream of water will be diverted around

the finger and spray out horizontally with some force.

The horizontal distance the water is projected is remarkable.

The best introductory article

available on the subject is still "Applications

of the Coanda Effect" by Imants Reba, which appeared

in the June 1966 edition of Scientific American.

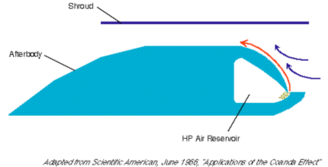

This

diagram shows a Coanda Thruster tested by Reba.

Air is ejected from a plenum at the front of the body.

A small step is inset into the surface of the body which

causes the ejected air jet to attach to the surface

and flow around it towards the upper surface.

A sheet of attached air called a Coanda Jet flows towards

the back of the thruster. This

diagram shows a Coanda Thruster tested by Reba.

Air is ejected from a plenum at the front of the body.

A small step is inset into the surface of the body which

causes the ejected air jet to attach to the surface

and flow around it towards the upper surface.

A sheet of attached air called a Coanda Jet flows towards

the back of the thruster.

In

so doing, it entrains by suction up to 20 times as much

air from the surrounding atmosphere as is in the jet

itself. A shroud placed around the body increases

the suction on the surrounding air even more.

Air

pressure on the front of the thruster is therefore reduced

by the entrainment suction so the body moves forward.

In addition, the afterbody made of flat angled segments

causes the attached Coanda jet or sheet to exert a positive

pressure on the rear of the thruster and so further

increase thrust.

We therefore have exactly the opposite situation to

a normal airfoil moving through air: instead of

positive air pressure on the front and negative pressure

on the rear, creating drag, we have Negative Drag - i.e.

Thrust.

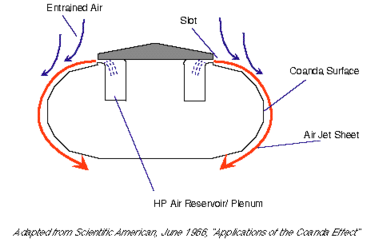

This

shows a model levitating device (hovercraft) tested

by Reba. The body of the device is made of short

flat surfaces, creating a so called Coanda Surface;

high pressure air ejected from an annular slot on the

top of the device flows around and down to wards the

bottom, entraining the surrounding air as it does so

and creating a partial vacuum on the upper surface -

a lower pressure region. Lift is therefore produced.

As with the thruster above, ambient air pressure is

increased below the device to increase lift. This

shows a model levitating device (hovercraft) tested

by Reba. The body of the device is made of short

flat surfaces, creating a so called Coanda Surface;

high pressure air ejected from an annular slot on the

top of the device flows around and down to wards the

bottom, entraining the surrounding air as it does so

and creating a partial vacuum on the upper surface -

a lower pressure region. Lift is therefore produced.

As with the thruster above, ambient air pressure is

increased below the device to increase lift.

Hydrofoil and Submarine Propulsion

Reba tested a model hydrofoil using a shrouded Coanda

thruster. The entrainment of the surrounding water

to produce thrust results in very little wake or noise.

Reba felt that a hydrofoil so equipped could reach speeds

of 80 knots. At about the same time in 1962, Stine

at the Huyck Corporation worked with Henri Coanda to

build a similar device using ejected steam for submarine

propulsion.

This concept has recently been re-invented by Australian

Alan Burns and developed by Pursuit Dynamics in the

UK. A 20 cm long "underwater jet engine" that

injects steam from an annular slot into an internal

Coanda nozzle is said to produce 30 HP output.

(See New Scientist, 1/3/03, P19).

Allied

Signal patented an internal Coanda nozzle using similar

principles in the late 90s. One application is

to eliminate the back pressure from the exhaust

of an internal combustion engine, but to instead suck

the combustion products out and so improve efficiency.

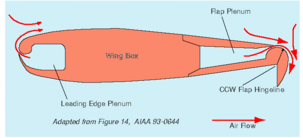

Circulation Control Wing

Circulation

Control Wing technology is one of the most important

potential applications of the Coanda Effect. Circulation

Control Wing technology is one of the most important

potential applications of the Coanda Effect.

The objective is to replace the lift devices on the

leading and trailing edges of a wing by use of Coanda

Surfaces and slot blowing instead.

The

diagram above is from AIAA 93-0644.

The first known use of this

"blown flaps" concept was on the prototype Boeing 707.

Boundary Layer blowing was successfully used on the

Hawker Siddeley Buccaneer to improve STOL performance

for aircraft carrier operations. The supersonic

TSR2 also incorporated blown flaps, allowing the 90,000lb

delta winged aircraft with a wingspan of only 37 feet

to achieve an approach speed of 130 knots: the

Concorde type droop nose was also eliminated since a

much flatter non alpha lift approach could be made.

In the late 1970s, Robert Englar tested a modified Grumman

A6 Intruder fitted with a prototype CCW system.

The aircraft was able to fly at less than 60 knots

and take off or land in less than 600 feet without catapult

or arrestor assistance.

Studies showed that a Boeing 737-100 weighing 105,000

lbs fitted with CCW and no headwind would take 3000

feet to clear a 50ft obstacle on take off (Sea Level,

ISA); the normal distance is 5000 feet. Landing

roll with no headwind would be 750 feet, compared

to 2000 feet for the conventional configuration.

A lightly loaded 737 (65,000 lbs) with a 20 knot headwind

would land in 300 feet with CCW lift devices.

CCW allows lift to be produced at Zero

Degrees Angle of Attack. Coefficient of

Lift (CL) of 8 at alpha = 0 was achieved

in tests.

CCW

has been criticised for requiring extra APU or engine

capacity to supply the bleed air to drive the slot blowing,

According

to Englar, a pressure differential of 13.8 psi at Sea

Level ISA is sufficient to produce a Coanda Jet

velocity equal to the speed of sound. Normal airfoils

achieve a CP of between -1.0 and -2.0; the

most efficient airfoil possible, the cylinder, has a

CP of -3.0. CCW equipped wings have

achieved CP of between -50 and -60, i.e.

the suction on the upper wing surface is 50 times the

freestream dynamic pressure.

Cross

feed can be used between the plena in each wing to maintain

flap blowing in case of an engine failure.

Engine

and APU manufacturers are studying a next generation

of APUs that would supply all the bleed air for pneumatic

systems, leaving the engines dedicated for thrust alone.

APU reliability will have to improve greatly before

this is achievable.

The X Wing

Helicopter

The

conventional helicopter is limited to a maximum forward

speed of about 200 knots; above that speed the decreasing

relative velocity of the leading edge of the retreating

blade with respect to the freestream air flow leads

to unsustainable loss of lift and lift asymmetry between

the forward going and retreating blades; if the helicopter

tried to fly even faster, the oncoming airstream would

impinge the trailing edge of the retreating blade causing

even more loss of lift.

Numerous designs have been put

forward since the 1950s for Compound Helicopters to

help solve this. The compound helicopter adds

a wing and thrust engines to transition to fixed wing

mode and unload the rotor at high speed.

Despite the great advantages

in efficiency, payload and range that this would bring,

no compound helicopter has been commercially developed.

Piasecki Aircraft have been trying to commercialise

this technology since 1955 and flew their first Vectored

Thrust Ducted Propellor (VTDP) designs in the 1960s:

in 2002 they were awarded a contract to convert an SH-60

to VTDP mode but this apparently was cancelled due to

disagreements over flight test rules.

Another solution is to use CCW

technology. In this application, the helicopter

rotor blades are constructed as Coanda surfaces.

A plenum and spanwise blowing slot run the length of

the trailing and leading edges, with a symmetrical cross

section to the rotor blade. Air is blown onto

the trailing edge of the forward going blades.

As the blades retreat, slot blowing is swapped onto

the leading edge of the blade, which is now a trailing

edge with respect to the forward motion of the helicopter.

This maintains lift on the retreating blades and theoretically

will allow forward flight speeds of 400 knots in pure

helicopter mode. Above that speed, fixed wing

mode is more efficient so the rotor is locked into place

to create an "X Wing". Differential slot blowing

is used in the transition phase to eliminate differential

lift as the rotor slows down.

NASA

Ames developed a fully functioning flight test vehicle

in 1979 to test this X Wing concept (right): apparently

it never flew due to engine bearing problems.

It is more than just a compound helicopter with a wide

chord rotor: the circulation control rotor can

maintain helicopter mode lift at high forward speed

and use differential blowing for lateral control. NASA

Ames developed a fully functioning flight test vehicle

in 1979 to test this X Wing concept (right): apparently

it never flew due to engine bearing problems.

It is more than just a compound helicopter with a wide

chord rotor: the circulation control rotor can

maintain helicopter mode lift at high forward speed

and use differential blowing for lateral control.

US Patent 4,626,171 "Rotor Blade Construction for Circulation

Control Aircraft" was then issued to United Technologies

(Sikorsky) in 1986 for the same technology.

The latest embodiment of this

idea - the Canard Rotor Wing - is a stopped rotor design

that does not as far as we know use circulation control

or slot blowing to increase maximum forward speed in

helicopter mode, or to control the transition from helicopter

to stopped rotor mode.

A search through the patent

literature shows that quite a number of stopped rotor

X Wing configurations have been developed, such as

- US Patent 4,711,415 to Northrop

for "X Wing helicopter Scout Attack Configuration"

- US Patent 5,405,104 for "Stopped

Rotor Aircraft Utilising a Flipped Airfoil X Wing"

- US Patent 4,573,871 to the US

Army for "X Wing Aircraft Circulation Control"

- US Patent 3,794,273 to Teledyne

Ryan for "VTOL Rotor Wing Drone Aircraft".

VTOL

craft development has remained completely unchanged

since the 1930s with the exception of the NOTAR No Tail

Rotor technology by McDonnell Douglas Helicopters. This

technology eliminates the danger and noise of the tail

rotor and provides impressive performance improvements.

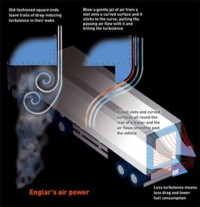

Drag

Reduction Spoilers for HGVs

A straightforward application of the Coanda Effect

has been the development by Robert Englar of spoilers

for Heavy Goods Vehicles. These could reduce fuel consumption

by up to 15% by reducing the negative pressure region

formed behind the trailer of a typical square edged

haulage vehicle.

Other Applications

Some

other applications and technologies that have been developed

using the Coanda Effect include:

- The

Gurney Flap

- Dual

Cavitating Hydrofoil Thrusters

- Drag

elimination and aerodynamic braking systems for automobiles

- The

NOTAR helicopter anti-torque system

- The

Flettner Rotor Wing

- The

Kline Fogleman Wing

- Wing in Ground Effect Vehicles

- The Carr Internal Wing (or Channel

Wing) Aircraft

References

Further Information

Further

information can be found in Meridian International's

1997 "Advanced Propulsion Systems Study". An updated

version will be coming out later in 2005.

|